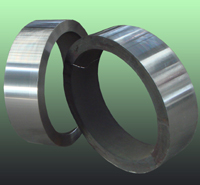

X50MnCr18-5 forged ring

2015-05-21 09:30:06 Origin: Remark:0 Click:

Material specification X50MnCr18-5 datasheet,X50MnCr18-5 Chemical, X50MnCr18-5 Ring forging, Bar, Wire rod, Sheet - steelmaking, ESR,Blooming,DIN X50MnCr18-5 Forging, hot Rolling, Heat treatment, Straightened, Ultrasonic test, Cold working, Machined. We also possess advanced precision machining equipments for further processing.

Technical Standards - DIN SEW 390 -1991 or By agreement.

Nonmagnetic Forged Ring For Steam Turbine Generator

TECHNICAL SPECIFICATION / DATASHEET - X50MnCr18-5

MATERIAL SPECIFICATIONS: DIN SEW 390 (1991) / JB/T 1268 -93

CHEMICAL COMPOSITION (WEIGHT %)

C (%): 0.40 ~ 0.60

Si (%): 0.30 ~ 0.80

Mn (%): 17.0 ~ 19.0

P (%)≤: 0.060

S (%)≤: 0.025

Cr (%): 3.50 ~ 6.00

Si (%): 0.30 ~ 0.80

Mn (%): 17.0 ~ 19.0

P (%)≤: 0.060

S (%)≤: 0.025

Cr (%): 3.50 ~ 6.00

Ni (%): -

Mo (%): -

V (%): -

W (%): -

Al (%): -

N (%): -

N (%): -

HOT WORKING, HEAT TREATMENT AND MECHANICAL PROPERTIES

Grade one

σb≥ /MPa: 895

σ0.2 ≥/MPa: 760

δ≥ (%): 25

σ0.2 ≥/MPa: 760

δ≥ (%): 25

ψ≥ (%): 35

Akv ≥/J: -

Akv ≥/J: -

Grade two

σb≥ /MPa: 965

σ0.2 ≥/MPa: 825

δ≥ (%): 20

σ0.2 ≥/MPa: 825

δ≥ (%): 20

ψ≥ (%): 30

Akv ≥/J: -

Grade three

σb≥ /MPa: 1035

σ0.2 ≥/MPa: 900

δ≥ (%): 20

σ0.2 ≥/MPa: 900

δ≥ (%): 20

ψ≥ (%): 30

Akv ≥/J: -

Akv ≥/J: -

TYPICAL APPLICATIONS

High-voltage electrical apparatus, bolts and nuts

Transformer tank

Generator

Preparation equipments

Electronics

Hot search:X50MnCr18-5 forged ring

Previous page:X50MnCr18-5

Last page:X50MnCrN18-5

Total list

Monthly rank

- 5AISI 422 SUH616 1.4935 X20CrMoWV12 Flat bar

- 4X22CrMoV12-1 +QT1

- 4AISI 422 Flat bar / S42200 Forgings

- 3AMS 5579D Forgings

- 3AISI 630 & 17-4PH & 1.4542 & S17400 Aging Steel

- 3Maraging steel 1.6359 / K92890

- 3S13800 bar, S13800 plate

- 3M-152 / S64152 / 1.4938 Forgings

- 345Cr14Ni14W2Mo Round bar, ESR ingot, Forgings

- 3B50A365B / 403Cb+ / 1.4913 Turbine Blade Steel